Every industry needs safety measures to guarantee the integrity of its employees and resources, that is why we specialize in a series of studies and evaluations that will allow you to be in line with current regulations and avoid risks and accidents that may cause human or material losses to your company.

Photovoltaic Systems

Consulting

At ALHER SEM, we offer consulting, supply, and specialized installation services for photovoltaic systems, focusing on the analysis, design, and technical evaluation of solar power solutions for service buildings, hotel developments, and industrial facilities.

Our approach goes beyond system sizing. We analyze the technical, regulatory, operational, and financial conditions of each project to ensure that the photovoltaic solution integrates correctly with the existing electrical infrastructure and provides real benefits in terms of energy efficiency, reliability, and return on investment.

We accompany our clients from the initial stages of feasibility, executive project development, supply, installation, and commissioning, ensuring the correct technological selection, regulatory compliance, and safe and sustainable operation over time.

Top projects:

Panasonic de México

Planta Gugar de Oaxaca

500 kWe

Grupo avant solar

Sexto Sol Energías I, Hercules Chihuahua

30 MWe

Grupo avant solar

Sexto Sol Energías II, Hercules Chihuahua

30 MWe

Grupo avant solar

Avant Energias renovables I, Moctezuma Coahuila

30 MWe

Grupo avant solar

Avant Energias Renovables II, Camargo Coahuila

30 MWe

Energy Efficiency

Consulting

At Alher Sem, we are committed to ensuring that the work carried out in your industry is carried out under an efficient and environmentally responsible environment, for this reason we support efforts to implement policies and reduce energy costs, providing management tools such as:

- Energy Management NOM ISO 50001.

- Energy audit.

- Evaluation of efficient technologies.

- Energy monitoring and measuring.

Protection Coordination and Arc Flash

Consulting

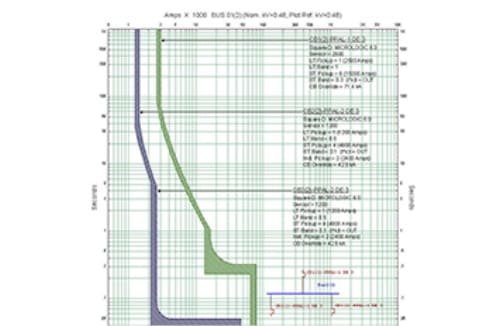

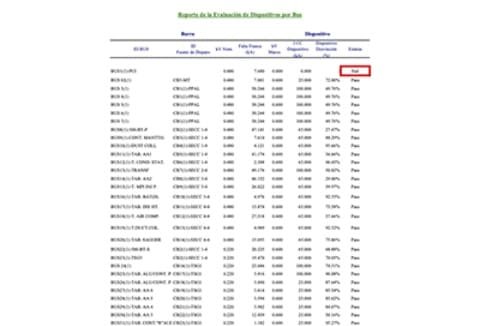

The electrical protection coordination studies will define the behavior of the elements of a protection system, with the objective of finding the least possible impact on the electrical system if short-circuit faults occur.

The Arc Flash study allows to evaluate how much energy will be released during an Arc Flash and what would be the affectation of the employees according to the distance they are located, as well as to determine limits in the protection area and the protective equipment to be used to provide the safest possible environment.

In order for the installations to operate safely and selectively in the event of a fault condition, we carry out a detailed analysis of electrical protection coordination and arc flash, using specialized software, protection characteristics and single-line diagram, carrying out the following:

- Physical verification of protection elements.

- Conformation of single-line diagram.

- Development of a software model of specialized load flows.

- Short-circuit analysis.

- Protection settings analysis.

- Arc flash analysis.

- Adjustments of protection elements.

We follow the standards C37, 141, 232, 399, IEC and the ANSI/IEEE standard 909.

LOTO Procedures

Consulting

The Lockout and Tagout Procedures for hazardous energies (LOTO Procedures) are applied as a protective measure for personnel prior to performing an intervention on industrial equipment or machinery. Their objective is to ensure that machines are free of hazardous energies that could cause injuries to workers during a preventive and/or corrective maintenance process, whether programmed or eventual.

Any comprehensive Lockout/Tagout service should follow the following points:

- Create a database of equipment, their energies and how to intervene on them.

- Perform risk analysis studies for the equipment.

- Based on the above points, LOTO cards and labels are prepared for each piece of equipment.

- Draft the LOTO procedures manual with the results of all the above.

- The company shall procure all appropriate interlocks for each hazardous energy of each piece of equipment.

- Train relevant personnel to ensure proper implementation of LOTO procedures.